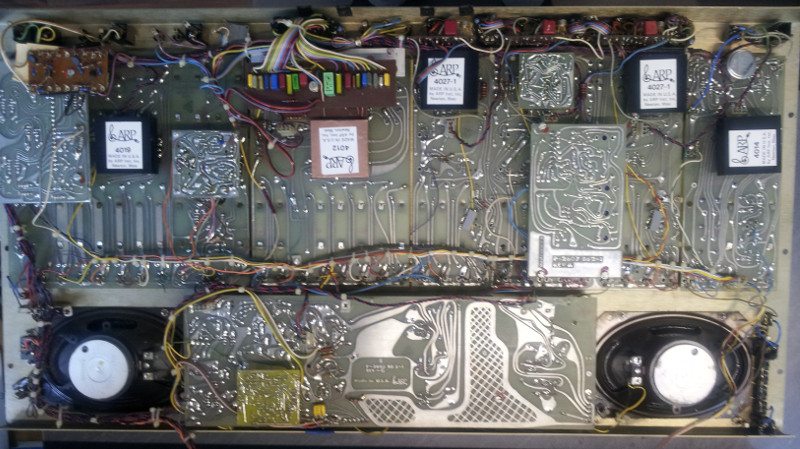

The hearts – the FVS has four of them – is the famous Oberheim SEM synthesizer module. Once intended for enthusiasts as an add-on to their modulars, it has all relevant connections on Molex connectors on its back side. Several of them are internally routed to other modules, but a modification of this FVS is also in preparation, making it into a modular hybrid.

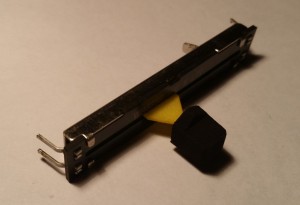

First of all, the SEMs need to be restored to a working state. Potentiometer cleaning is a bit more complicated because of the special pots used for coarse and fine setting of the VCO frequency.

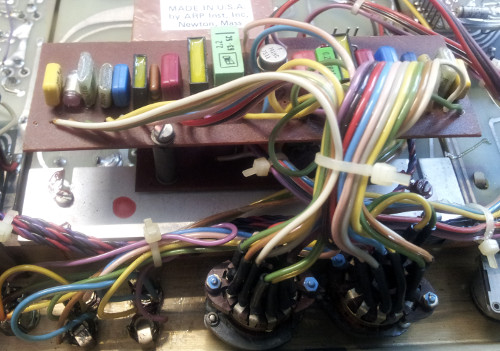

Here’s how this potentiometer looked when disassembled:

After potentiometer and switch maintenance the SEMs will be “re-capped”, tested and repaired where necessary.

I got one working SEM in a break-out case in addition to verify things which was told to sound a lot better than the SEMs of a Two Voice that I have not looked at so far.

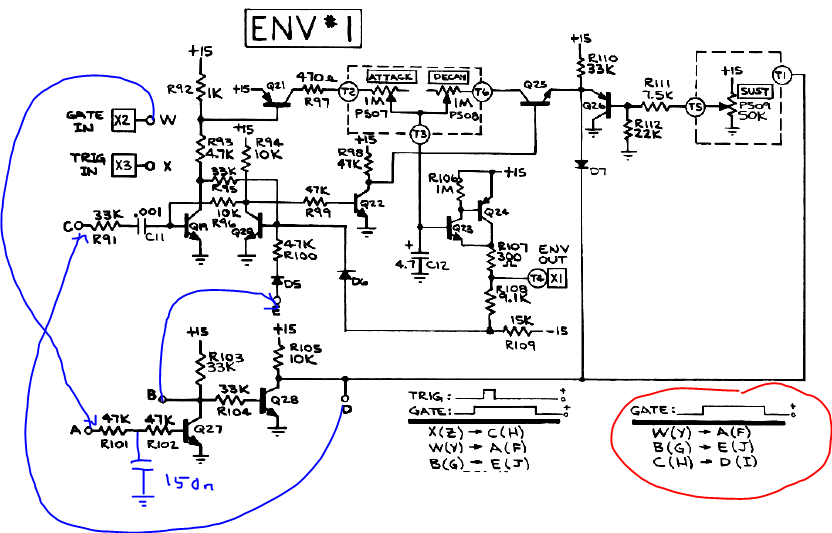

So I compared the SEMs from the FVS with the stand-alone SEM and found that the single SEM was lacking a 150nF capacitor in the gate input circuitry that were present in the FVS SEMs.

I wonder which impact this capacitor might have on sound – it clearly slows down the slope of the gate signal to the trigger circuit and envelope generator.

Will it affect the “snappiness” of a short attack time to an audible extent? Hard to say from the circuit, probably from simulation, but to make things clear I will do some testing once the first SEM is up and running.

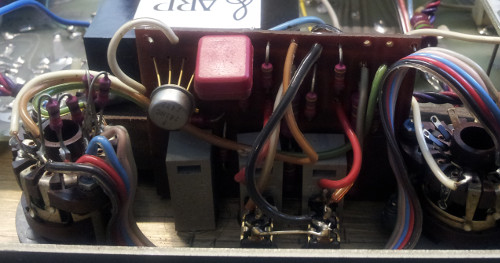

Here’s the additional capacitor (no comments on my artwork!)