Honestly – serious production with Midi-to-CV to control analog synthesizers seems to be impossible. 7 bits translates to quite large steps in the control voltage. But how about using an studio grade 18 bit A/D – D/A box driven via ADAT?

If a Creamware A16 comes into your mind, you’d better think twice about it. There are some reasons converters like this are hard to modify for precise DC:

- First of all, the inputs are capacitively coupled. But of course it can’t be as easy as just bypassing the caps…

- Both the ADCs (Philips SAA7367) and the DACs (Philips TDA1305) use single +5V supply. This implies that the analog signals need to be centered around an internally generated reference voltage

- The reference voltages are not quite precise. Although their long-time stability is very good, the initial accuracy is 5% or worse. Therefore also the signal range varies from chip to chip.

- The ADCs have an integrated high pass filter to remove DC offsets, but fortunately it can be easily disabled by lifting up one pin and strap it to ground

The engineers saved some parts by not subtracting the DAC refence voltage from the outputs, but lifted the ground potential of all 32 jacks by the reference of the first DAC (channels 1 & 2). For this purpose, a high power voltage follower with massive decoupling on the output was designed. As the reference voltages differ from DAC to DAC, this approach would not work for DC, so I removed the circuitry and connected the jack ground to circuit ground.

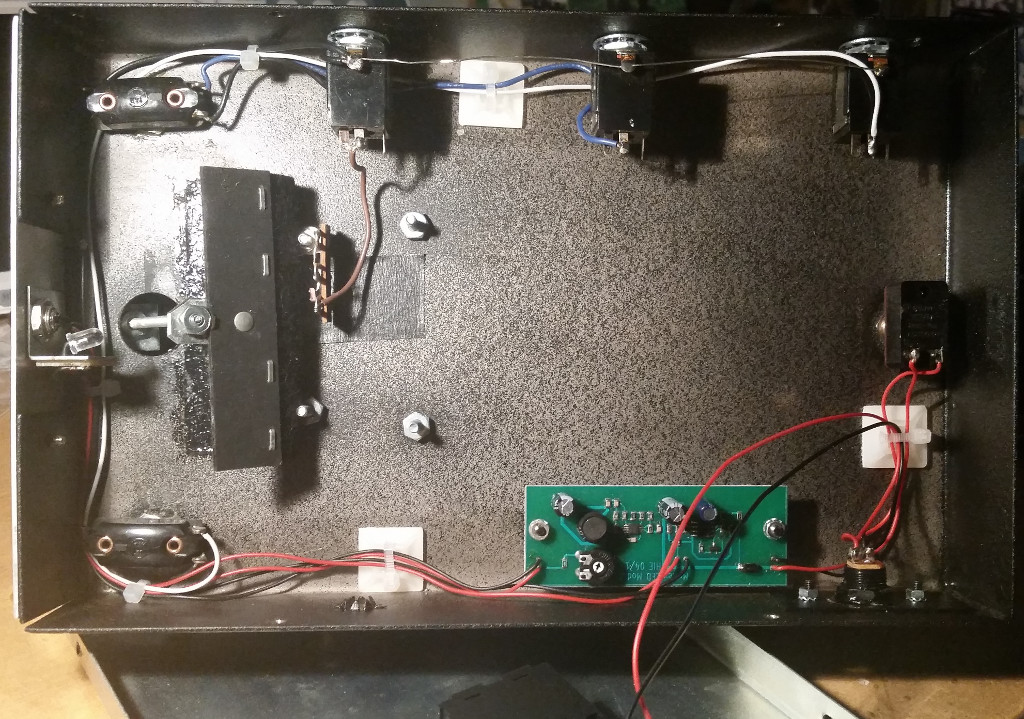

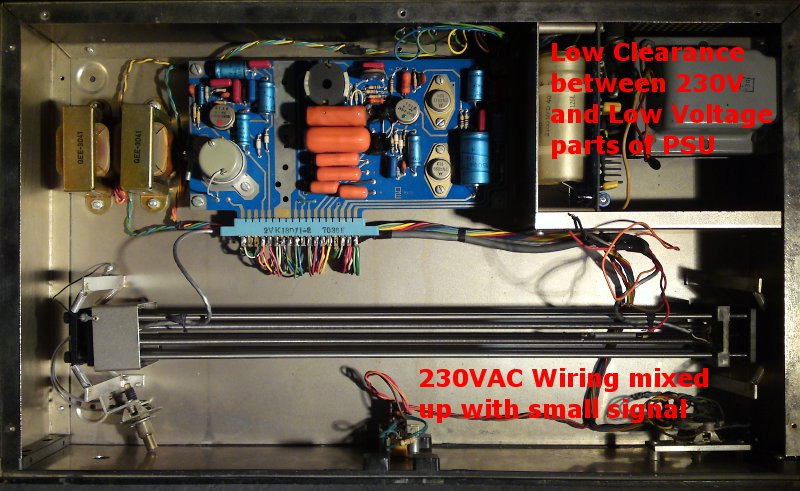

When I was working on the PSU – a quite strange design by the way – I modified two regulators to supply +/-7.5 volts to the op amps because in the original design the op amp supplies were a) somewhat too low and b) shifted by the same amount the jack grounds are lifted beyond ground.

A last modification to the PSU applies to precision and stability: the analog supply which influences the reference voltages was derived from a LM317’s output by means of a voltage divider and a power voltage follower – including thermal drift. To improve the absolute precision of the converters, I replaced the resistive voltage divider with a TL431 shunt regulator.

But things became even worse…

While doing some measuring with the ADAT in and out jacks connected I found that the outputs are inverted with respect to the input voltage. With an ADAT box and appropriate software I was able to determine that the inversion takes place between ADAT-In and the analog output of the DACs, so another inversion in necessary here, including subtraction of the reference voltage.

This was accomplished by inverting the reference output of each DAC chip (there’s one reference per chip), but due to the rather high impedance of the reference pin, a voltage follower was necessary too. The inverted reference and the DAC output voltage are then summed up with an op amp. This op amp drives the output jack’s tip connection via 300R for protection and EMI purposes, while the feedback to the adder is connected after the protection resistor so that the input impedance of the connected load does not influence the output voltage up to a certain grade.

Both the reference and the DAC output are summed up via a series connection of a fixed and a variable resistor to allow to compensate the differences between the DAC chips.

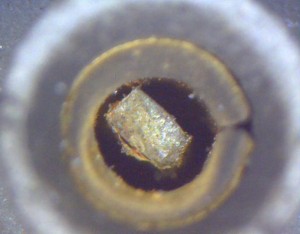

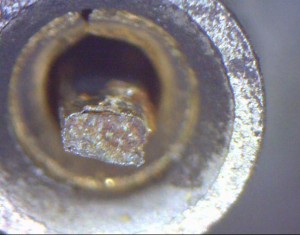

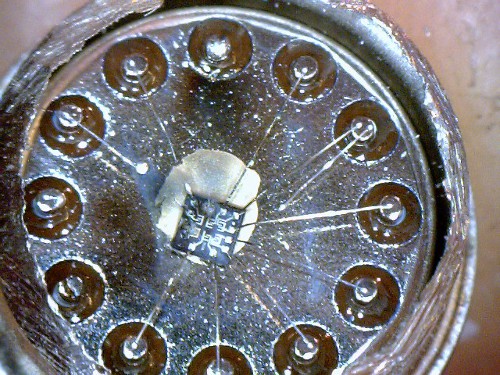

By cutting several traces and soldering some components to the IC pins, not to mention the tons of RTV used to mount the variable resistors, it was possible to build both adders, the voltage follower and the inverter stage around the op amps previously used to drive the outputs.

Really…?

Actually – not. Originally NE5532’s were used, but as I needed to add another 8 op amps (read on to learn why), the current draw would probably have blown the PSU some day. The whole 1.3 amps were already fed through one single LM337, so I decided to remove all 5532’s (offset voltage: 0.5mV typ) and replace them by MC33078’s, which offer an improved offset of 0.15mV typ. at less than half the power consumption.

A similar treatment applies to the input channels. In the original circuit, the positive input (on the ring of the phone jack!) is capacitively coupled and mixed together with the inverted tip signal using the input op amp of the SAA7367 ADC as summing amplifier. For the DC modification it is required to add the DC input signal and the reference voltage, which is generated individually for each ADC input, and feed the result without inversion to the ADC.

Unfortunately this requires two op amps per channel – but there is only one NE5532 for two channels. Besides replacing the 5532 with the above mentioned MC33078 I piggy-packed another 33078 which inverts the inverted sums for two channels.

Obviously this is only possible with some additional wiring and rather bohemian component placement.

Not to mention another ton of RTV to keep the potentiometers in place – one for the input gain and one for the offset voltage, as for the DAC channels.

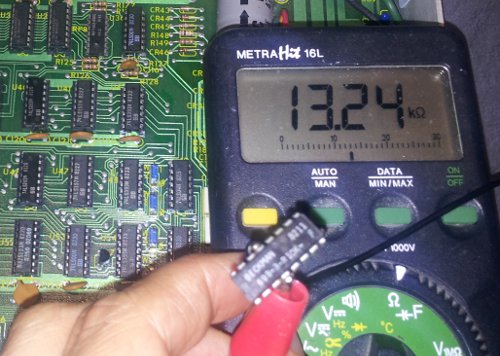

After all this makes 24 ICs and about 250 resistors to be removed and then about 200 new resistors, 16 capacitors, 32 ICs and 64 (as in six-ty-four) multi-turn potentiometers to be installed, not to mention the modifications on the PSU board.

After initial calibration, the zero offset of the DACs was kept within 1mV over several days. The gain was calibrated so that 5.0 volts input results in a reading of -1dBFS. This was recorded as a reference signal and used to adjust all output channels to 5.000 volts.

Stay tuned for some more photos…