The SCI Prohet 5 Synthesizer has thermal issues in the power supply. SCI’s attempt to make do with a single CT secondary winding results in a voltage of up to 25VDC before the 7805 series regulator. The lack of a decent heatsink makes this even worse. Several techs have been rebuilding the stock PSU with either an additional tranformer or by replacing the transformer with a new one with an additional winding, supplying around 9 volts to an additional rectifier.

This modification also requires some work on the reset circuitry, otherwise the RAM contents might be damaged on shutdown. Other typical work covers replacing the thermal interface material, the big filter capacitors and the tantalum capacitors on the PSU board.

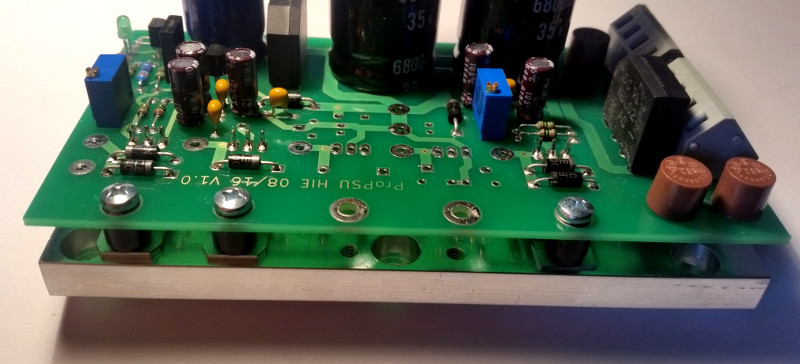

I decided to somewhat standardize the PSU maintenance of Prophet 5’s by designing a drop-in replacement PSU board I called the ProPSU. In order not have to temper with the name plate I made a aluminium heat spreader that is tightened to the back (use of some thermal compound is highly advised!) by re-using three of the original screws. The ProPSU board itself will be, after the cable harness is soldered to the ProPSU, bolted to the readily attached heat spreader by means of 3 or 5 M3x16 machine screws.

The ProPSU can be used for both Rev.2 and Rev.3 Prophet 5’s, with either the +12/-5 volts rails for the 2708 EPROMs provided or missing. Both 15V supplies can be adjusted by means of multi-turn presets. An on-board reset circuit switches the “+20V” rail to the mainboard’s reset generator, simulating a quickly discharging filter cap when the +5V supply drops below 4.75 volts. On turn on, the delay of the reset circuit ensures that all voltages are stable.

Ready to use ProPSU for late Rev.3 or modified Prophet 5 (new EPROMs, no +12/-5V required)

Mounting detail: the heat spreader bar is attached to the bolts of the old PSU’s regulators, after that the ProPSU

PCB is mounted to the heat spreader (isolation washers not shown here)