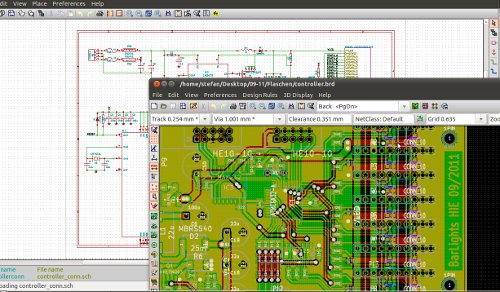

The Realton Variophon, a quite rare electronic wind instrument, is a frightening example how ignorant engineers can be when it comes to safety. While the whole circuit is a very interesting design and far from amateurish, the power supply is a completely no-go. To illustrate what I’m writing about, here’s a photo of the amplifier PCB that carries the mains fuse and switch connections:

- mains input is a standard IEC jack with the PE left unconnected, although exposed metal parts are present, but no proper isolation

- the mains wiring are – 2 AWG28 litz wires from the IEC jack to the board above and 2 AWG 28 wires back to the mains transformer

- those AWG28 wires are part of a 20 conductor flat cable, entering the PCB in the photo via pins 19 and 20 of the header

- the track passing the mounting screw, that is actually in direct contact with the metal front plate, is isolated with a small nylon washer

- the first and only fuse can be seen after the mains switch

- next to the 4 header pins carrying 230VAC are secondary circuits which are in direct contact with the metal parts of the instrument

The only valid bet would be what happens first – electric shock or fire. This one obviously needs a serious rework.